常熟國強和茂管材有限公司

Sinupower Heat Transfer Tubes Changshu Ltd.

400-100-7068

微信號:WEIXINHAOMA

微信號:WEIXINHAOMA

Introduction to Aluminum and Aluminum Alloy Materials

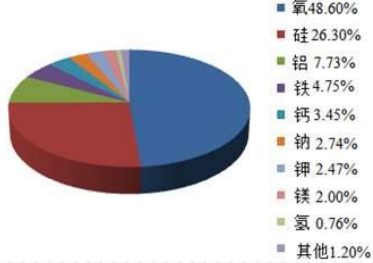

Aluminum is the most widely distributed and abundant metal element in the Earth's crust, accounting for approximately 7.3-8.3% of the total mass of the crust, second only to oxygen and silicon; Aluminum was discovered in the early 19th century and began to have production scale in the early 20th century; Hard aluminum alloy was invented in the early 20th century and was widely used in the military industry during World War I.

Aluminum alloy: an alloy based on aluminum with a certain amount of other alloying elements added, which is one of the light metal materials.

Aluminum alloy vs steel

Aluminum alloy has low density, moderate strength, high specific strength, and specific stiffness; Excellent corrosion resistance; High thermal conductivity and electrical conductivity; Medium elongation, plastic processing requires strict control of process parameters; The welding difficulty is slightly higher.

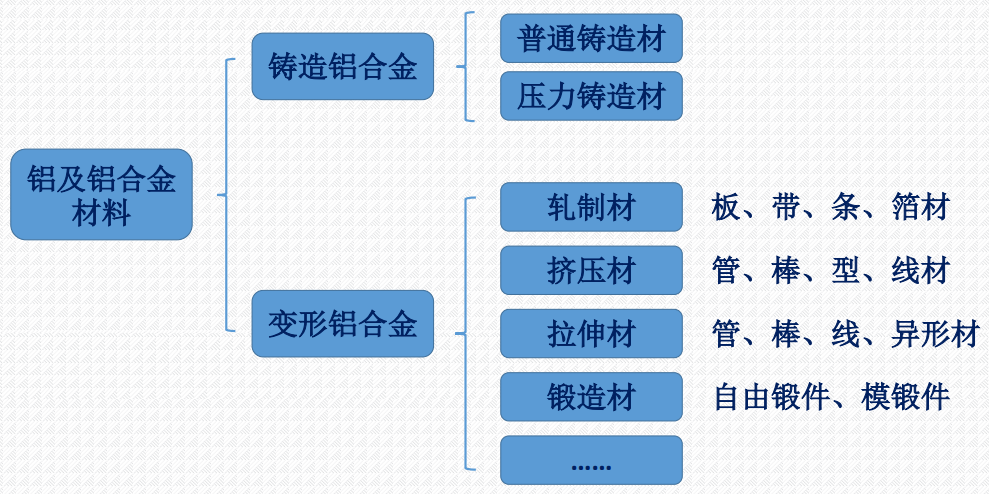

Classification of Aluminum and Aluminum Alloys by Processing Method

Casting aluminum alloy: an aluminum alloy with the desired shape and structural properties obtained by casting it into various models under certain temperature, speed, and external force conditions, utilizing the good fluidity and fillability of aluminum alloy melt.

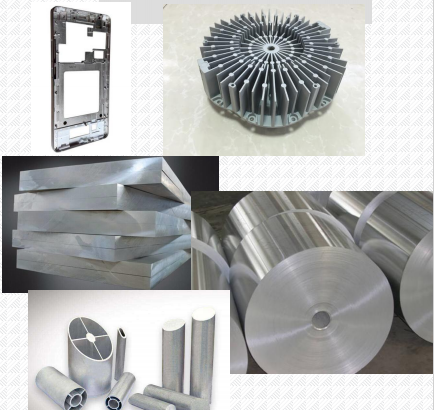

Deformed aluminum alloy: Various semi-finished aluminum alloys such as plates, pipes, bars, wires, and profiles made from aluminum ingots melted and cast with alloy ingredients as raw materials and processed by various pressure processing methods (rolling, extrusion, stretching, forging, etc.).

Cast aluminum alloy and deformed aluminum alloy

The main difference between cast aluminum alloy and deformed aluminum alloy is that the content of alloying element silicon in cast aluminum alloy exceeds that in most deformed aluminum alloys; Deformed aluminum alloy has a dense structure, uniform composition and properties, high strength, and good plasticity; Aluminum alloy casting has good processability, is less limited by component structure design, and has high production efficiency; Casting aluminum alloy has good casting performance and can be used to make complex shaped parts; No need for large additional equipment; It has the advantages of saving metals, reducing costs, and reducing working hours, and is widely used in the aviation and civil industries. It is also used to manufacture parts such as cylinder heads, transmissions, and pistons for automobiles, casings for instruments and meters, and pump bodies for superchargers.

Deformable aluminum alloy plays a major role in the materials used in aviation and aerospace products, such as aircraft skins, main beams, frames, ribs, landing gear parts, conduits, rivets, etc. It is also widely used in shipbuilding, automotive, and construction industries.

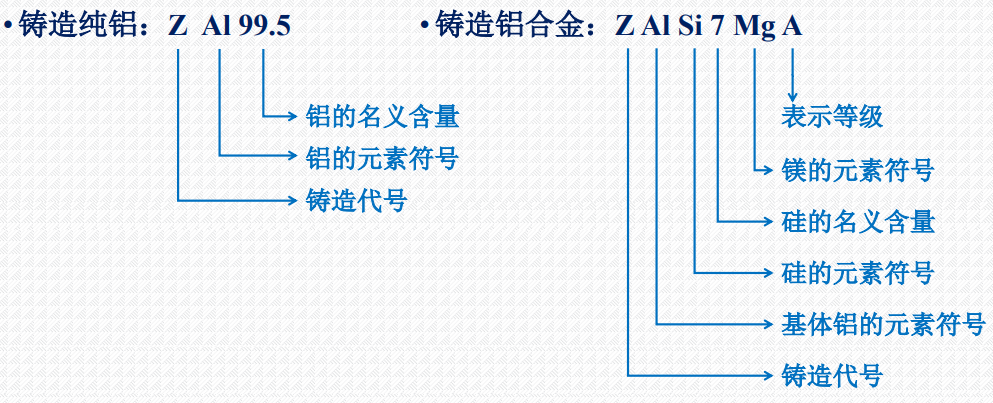

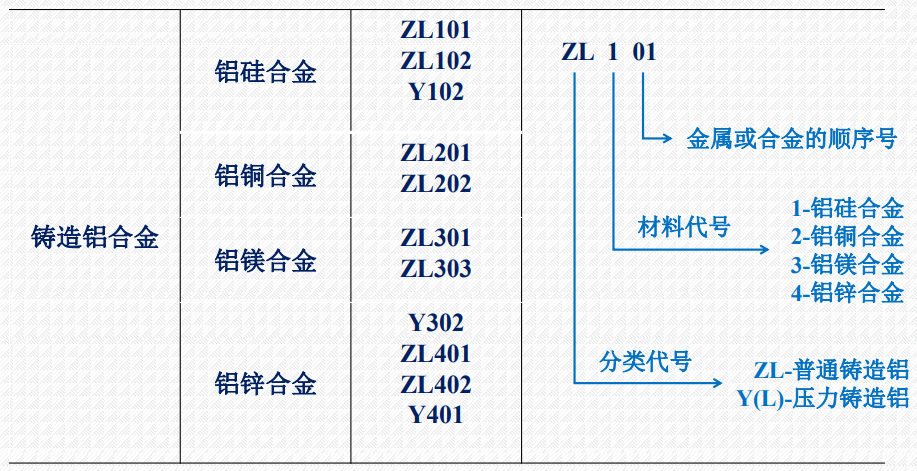

Method for designation of cast aluminum alloy grades (GB/T 8063-2017)

At present, there is no unified standard for casting aluminum alloys internationally, and each country (company) has its own alloy naming and terminology. According to Chinese standards, the cast non-ferrous metal grades consist of "Z", the element symbol of the base metal, the symbol of the main alloying element, and a number indicating the nominal content of the alloying element; When there are more than 2 alloying elements, the alloy grade should list the element symbols and their nominal contents that are sufficient to indicate the main characteristics of the alloy; The symbols of alloy elements are arranged in descending order of their nominal content; Except for the nominal content of the matrix element, which is not indicated, the nominal content of other alloy elements is indicated after the symbol of that element.

Casting aluminum alloy code

Method for designation of deformed aluminum and aluminum alloys (GB/T 16474-2011)

The naming method for deformed aluminum and aluminum alloy grades adopts a four character system: the first, third, and fourth digits are Arabic numerals, and the second digit is an English capital letter; The first digit represents the group of aluminum and aluminum alloys; The second digit or letter represents the modification of the original pure aluminum or aluminum alloy; The last two digits indicate the purity of different aluminum alloys or aluminum in the same group; International four digit system grades can be directly referenced. For example: 7A047075.

Groups of deformed aluminum and aluminum alloys

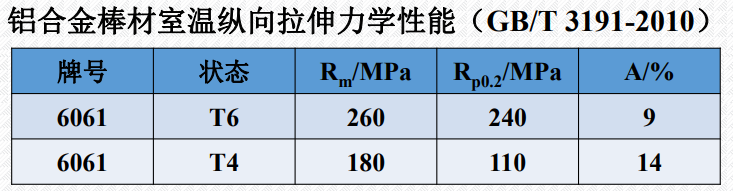

State code for deformed aluminum and aluminum alloys (GB/T16475-2008)

Basic state codes for deformed aluminum and aluminum alloys: F (free working state), O (annealed state), H (work hardened state), W (solution heat treatment state), T (heat treatment state).

The performance and state of aluminum alloy materials are directly related

Deformed aluminum and aluminum alloy grades

Aluminum alloy grades used in China: LG1、LD10; Classified by alloy properties and applications: industrial pure aluminum (L), industrial high-purity aluminum (LG), coated aluminum (LB), rust proof aluminum (LF), hard aluminum (LY), ultra hard aluminum (LC), forged aluminum (LD), special aluminum (LT), etc; Generally, it can correspond to four character system grades, which can be found in GB/T 3190-2008.

Development Status of Aluminum Alloy Materials in China

China is a major producer and consumer of aluminum alloy materials; Aluminum alloy materials have a wide range of applications in transportation, marine, aerospace and other fields, especially in some lightweight key components of automobiles, airplanes, aerospace, ships and other fields. Aluminum alloy materials are irreplaceable; China is a country with a large production of aluminum materials and a large scale of production equipment in the world; At present, the vast majority of aluminum alloy materials in China belong to mid to low end products, and some products still need to be purchased at high prices from abroad with outdated processing levels and poor product stability.

Development Goals of Aluminum Alloy Materials in China

2019 Research Report on the Development Strategy of Basic Materials (Nonferrous Metals) by the Chinese Academy of Engineering. Based on the actual situation in China and the bottlenecks encountered in the aluminum alloy field, the China Nonferrous Metals Association proposes the following mid-term development goals: by 2030, high-performance aluminum alloy materials will reach international standards, with some reaching international good levels, and the comprehensive mechanical and process properties of materials will meet the requirements of modern manufacturing industry indicators; By 2035, aluminum alloy materials will reach a good international level, achieving self-sufficiency and export of the vast majority of aluminum alloy materials, and realizing the development of the global aluminum alloy industry.

New progress in aluminum alloy materials in China

There is an urgent demand for large-sized and high-performance aluminum alloy materials in downstream application fields; Refinement of microstructure; By adding lithium or rare earth elements, etc; Through post-processing technology: multiple precision rolling, large deformation, etc; Aluminum based composite materials; Powder metallurgy aluminum alloy; Spray forming, coagulation forming, and thixotropic forming.

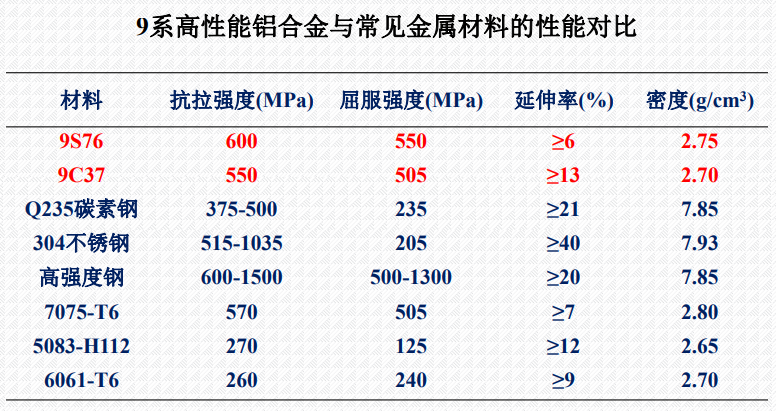

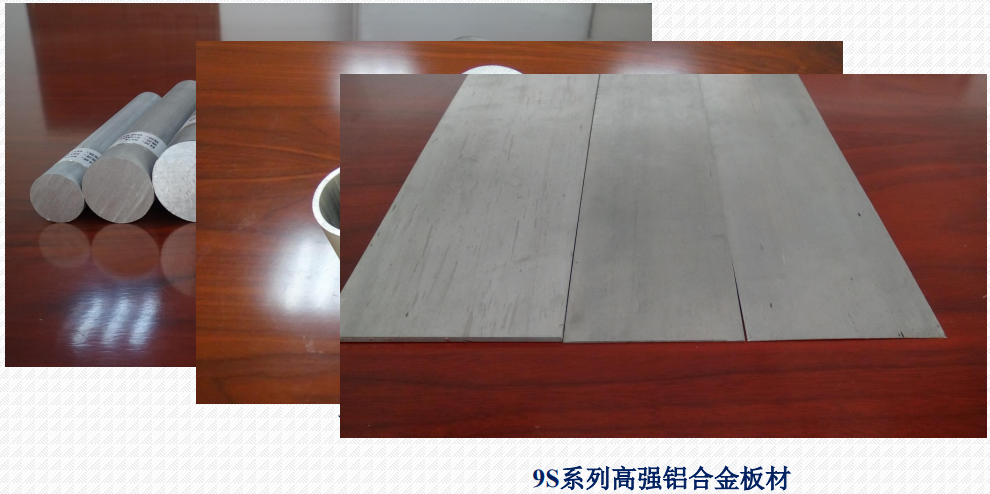

9 series high-performance powder metallurgy aluminum alloy

The research and development achievements of Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, which have taken more than 20 years; Incubation Project of Qingdao Zhongke Applied Chemical Technology Research Institute; The world's industrialized powder metallurgy aluminum alloy projects; Using mechanical alloying+semi-solid forming/powder metallurgy production technology, a series of special aluminum alloys with high strength (9S), high corrosion resistance (9C), high temperature service resistance (9H), low expansion and high wear resistance (9E) are prepared; It fills the gap in aluminum alloys in China and can replace imported 7075, 5083, CZ42, and 4032 aluminum alloys.

Property

Special aluminum alloy materials prepared by powder metallurgy method have high strength, stable performance, and significantly better indicators than traditional aluminum alloys produced in industrialization; The mechanical performance indicators of materials in the three-dimensional direction are basically the same.

Molding method

Excellent sintering process can achieve good performance without aging treatment, and the process is simple.

Welding performance

The micro reinforcement mechanism of 9-series aluminum alloy material shows no significant decrease in strength at the friction welding joint.

Exploration of the Application of Aluminum Alloy in the Field of Home Appliances

Discussion on the Application of Aluminum Alloy in Home Appliance Field - Sheet Metal

Aluminum plate has better corrosion resistance than steel plate; Ordinary anodizing can improve aesthetics; Hard anodizing/micro arc oxidation can improve wear resistance and safety; Can be used for panels, structural boards, drawers, etc; Stain resistant, sun resistant, and not easily scratched.

Possible technical difficulty: Uniformity of surface treatment for large-sized boards.

Discussion on the Application of Aluminum Alloy in the Field of Home Appliances - profiles and pipes

Aluminum alloy profiles can replace steel and be used as structural support materials for household appliances; Thin walled tubes can be used as heat exchange tubes for air conditioners/refrigerators, replacing copper tubes; 9C1 * series aluminum alloy, with over 99% aluminum composition; The tensile strength reaches over 300MPa, and the thermal conductivity is 210W/m ? K ±; Corrosion resistance and good refrigerant fluidity.

Discussion on the Application of Aluminum Alloy in the Field of Home Appliances - Spare Parts

Replace alloy copper to produce refrigerator/air conditioner connectors, direct connectors, etc; ρ(9S)=2.80,ρ(9C)=2.70,ρ(H62)=8.93,ρ(T2、T3)=7.83; Replace steel by producing bolts and nuts; Prevent electrochemical corrosion of the shell; Improve the comprehensive performance of electrical appliances.

Discussion on the Application of Aluminum Alloy in the Field of Home Appliances - Inner Tank of Water Heater

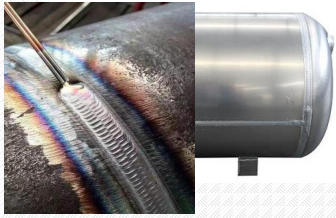

At present, steel plate bending, welding, and enameling processes are used, resulting in uneven welds that are prone to corrosion and leakage, affecting their service life.

Suggestion: Replace with an aluminum alloy inner liner.

Option 1: Extrusion tube+Friction Stir Welding+Micro arc Oxidation, Option 2: Aluminum plate bending+Friction Stir Welding+Micro arc Oxidation.

Friction stir welding has a smooth weld seam and good reliability; After micro arc oxidation, the surface of the inner liner is coated with alumina ceramic layer, which is safe and non-toxic.

Discussion on the Application of Aluminum Alloy in Home Appliance Field - Vortex Disc

New energy vehicle air conditioners widely use scroll compressors, which are small in size and have high working efficiency; Aluminum alloy vortex discs are lightweight, have low vibration, and low noise; A certain foreign brand of household air conditioner uses a vortex compressor with an aluminum alloy dynamic disc, achieving an energy efficiency ratio of 3.6.

traditional method

Low pressure casting; Liquid forging; Hot forging; Back pressure molding; 4032 aluminum alloy; Room temperature tensile strength 360MPa, hardness 110HB.

New materials and new processes

Powder precision forging forming technology; The dimensions of forged products are similar to those of finished parts; Can achieve minimal or no cutting; The forging has good strength and high temperature resistance. 9E series aluminum alloy: room temperature tensile strength 450MPa, hardness 135HB; Tensile strength at 350 ℃ 180MPa; The highest heat-resistant temperature can reach 450 ℃.

Exploration of Aluminum Alloy Application in Home Appliance Field - Inner Bucket of Drum Washing Machine

At present, the inner bucket of drum washing machines is mostly made of stainless steel material; Replace stainless steel with high-strength and corrosion-resistant aluminum alloy; Can reduce weight by more than 50%; Theoretically, it can improve efficiency and reduce noise.

Washing machine no-load power